A newsletter dedicated not only to news and trends in agricultural commodity prices, but also to potential developments and changes in feed formulations for different livestock. The IDENA formulation team hopes you enjoy reading it!

In animal nutrition, inter-batch transfer refers to the presence in a batch of feed or raw material of a residual fraction from a previous batch. This is the result of incomplete emptying or cleaning of the equipment used for manufacturing, storage or transport. This type of carryover must be controlled in order to guarantee feed quality, particularly when using additives, medicines or other substances that need to be controlled.

Various control processes are implemented to reduce this risk to an acceptable level. Here we present all of these measures as well as the main regulatory requirements governing their application.

Health risks: Unintentional exposure of animals to active substances such as coccidiostats, antibiotics, GMOs, etc.

Control through design:

Risks of non-compliance: failure to meet the requirements specified in the specifications and exceeding internal thresholds or regulatory maximum levels for additives (Regulation (EC) No 1831/2003) and undesirable substances (Directive 2002/32).

Control through procedures: Define and apply manufacturing sequences (increasingly sensitive food campaigns), purge cycles, drainage/cleaning protocols and strict planning rules for batches containing hazardous substances.

Implement an Inter-Batch Transfer Control Plan (PCTIL) with a choice of tracers (additives, analytical markers, external tracers) and targeted controls to verify residual levels after purging or changing campaigns.

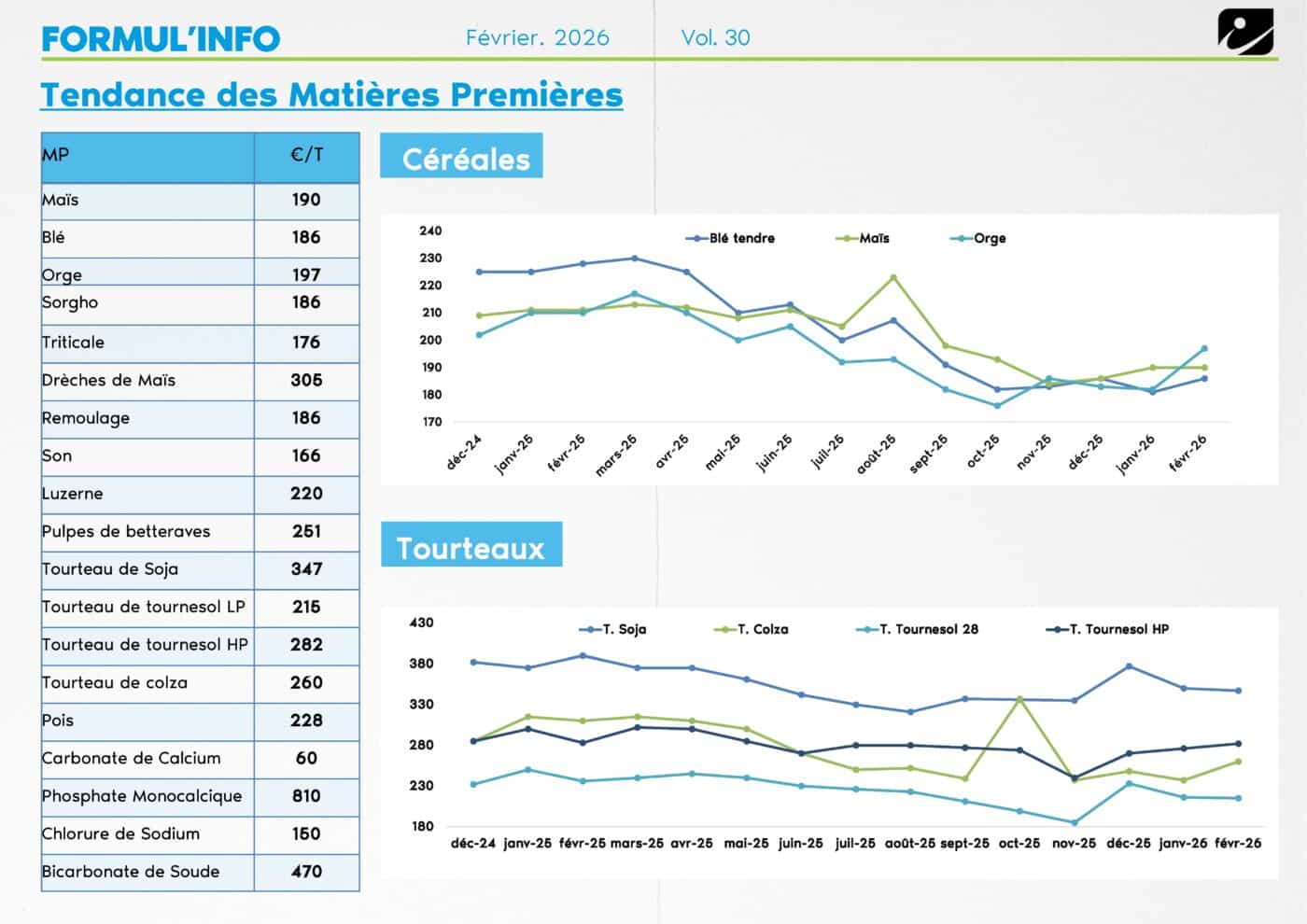

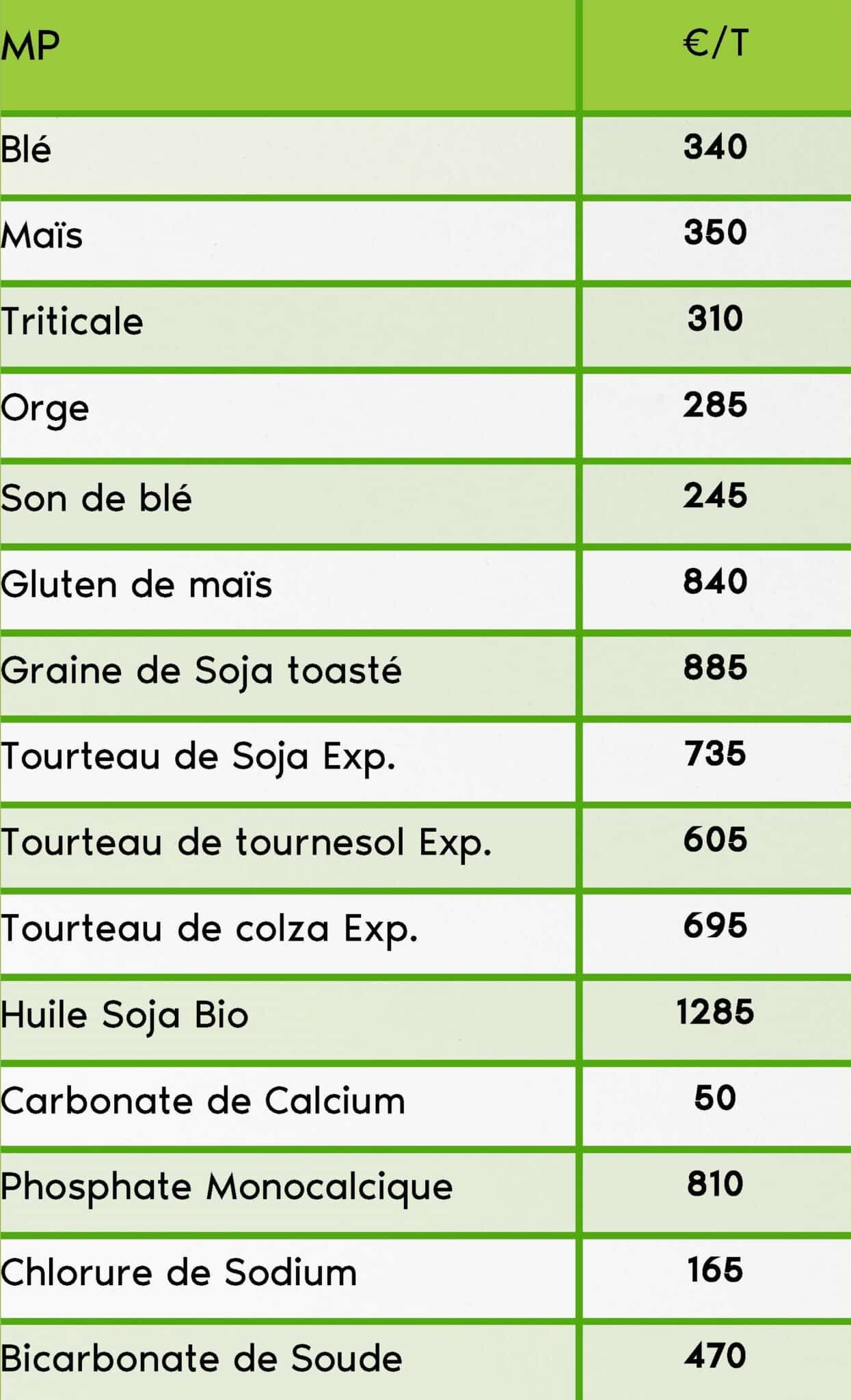

In February, there was a slight increase in cereal prices. Oilseed meal prices remained fairly stable.

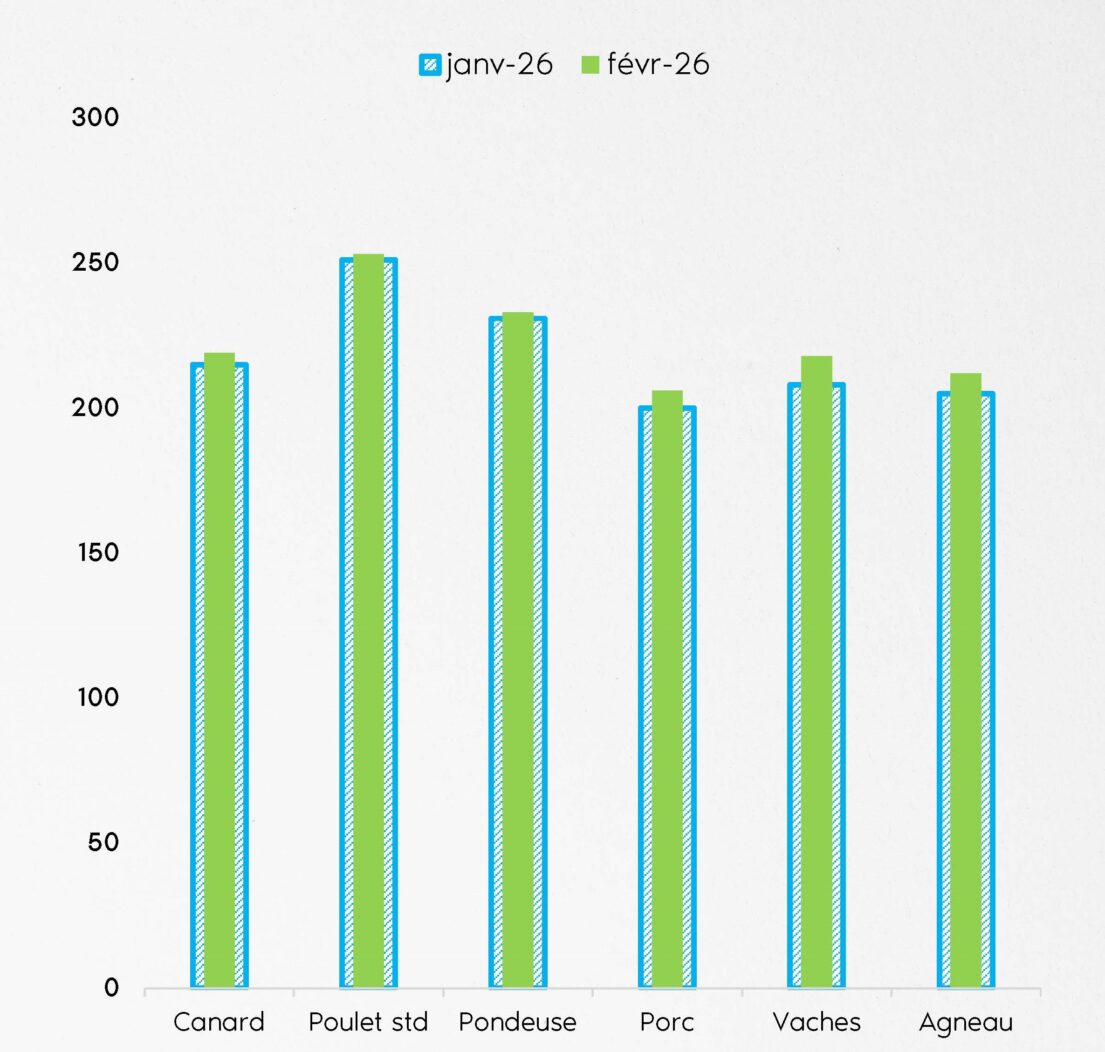

This month, there has been a slight upward trend in prices for monogastric and ruminant feed.

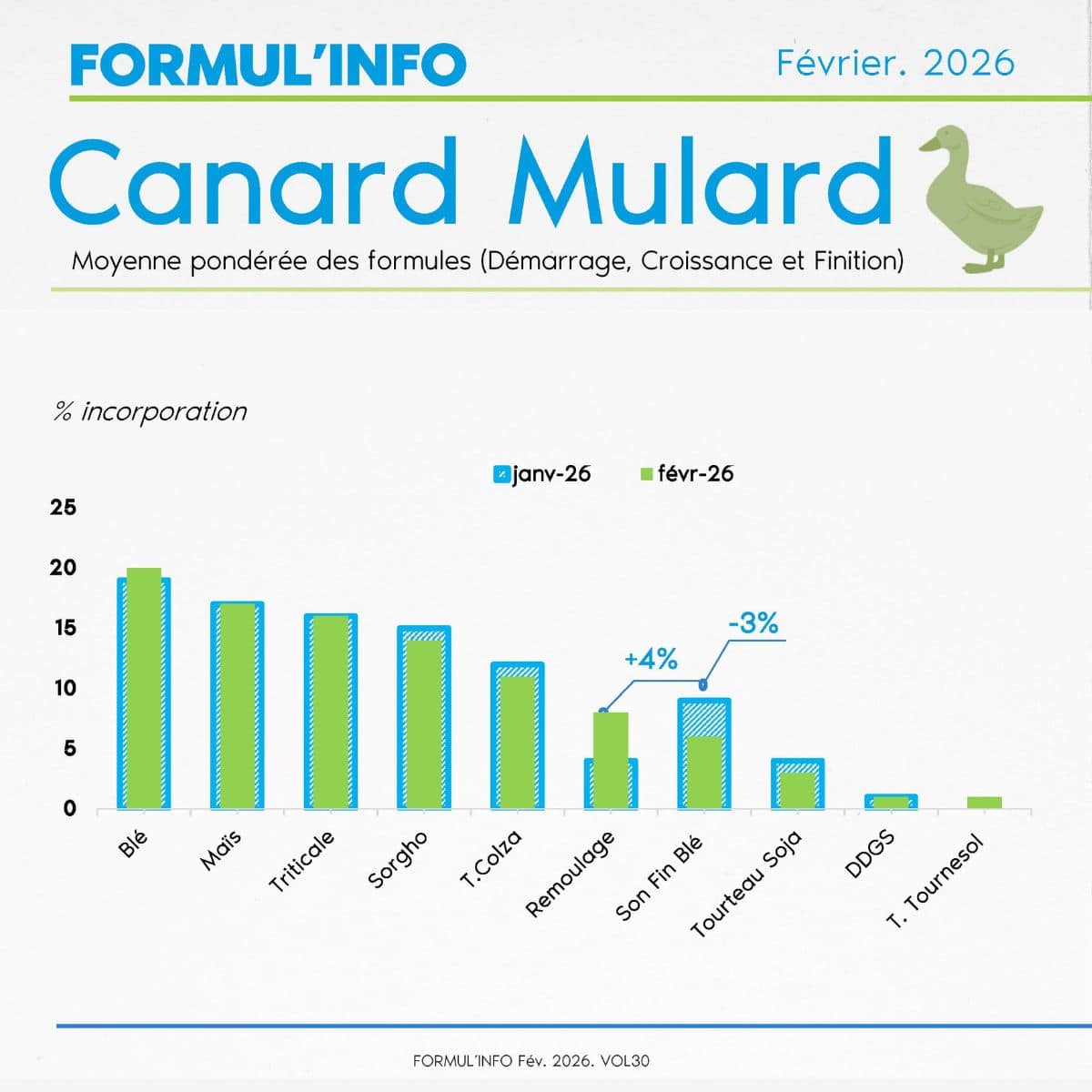

The cereal profile is similar to that of January, with a slight decrease in sorghum in favour of wheat. Cereal co-products are stable, with a balance between meal and bran. However, the profile of protein raw materials has changed. Sunflower has returned, offsetting a decline in soya and rapeseed.

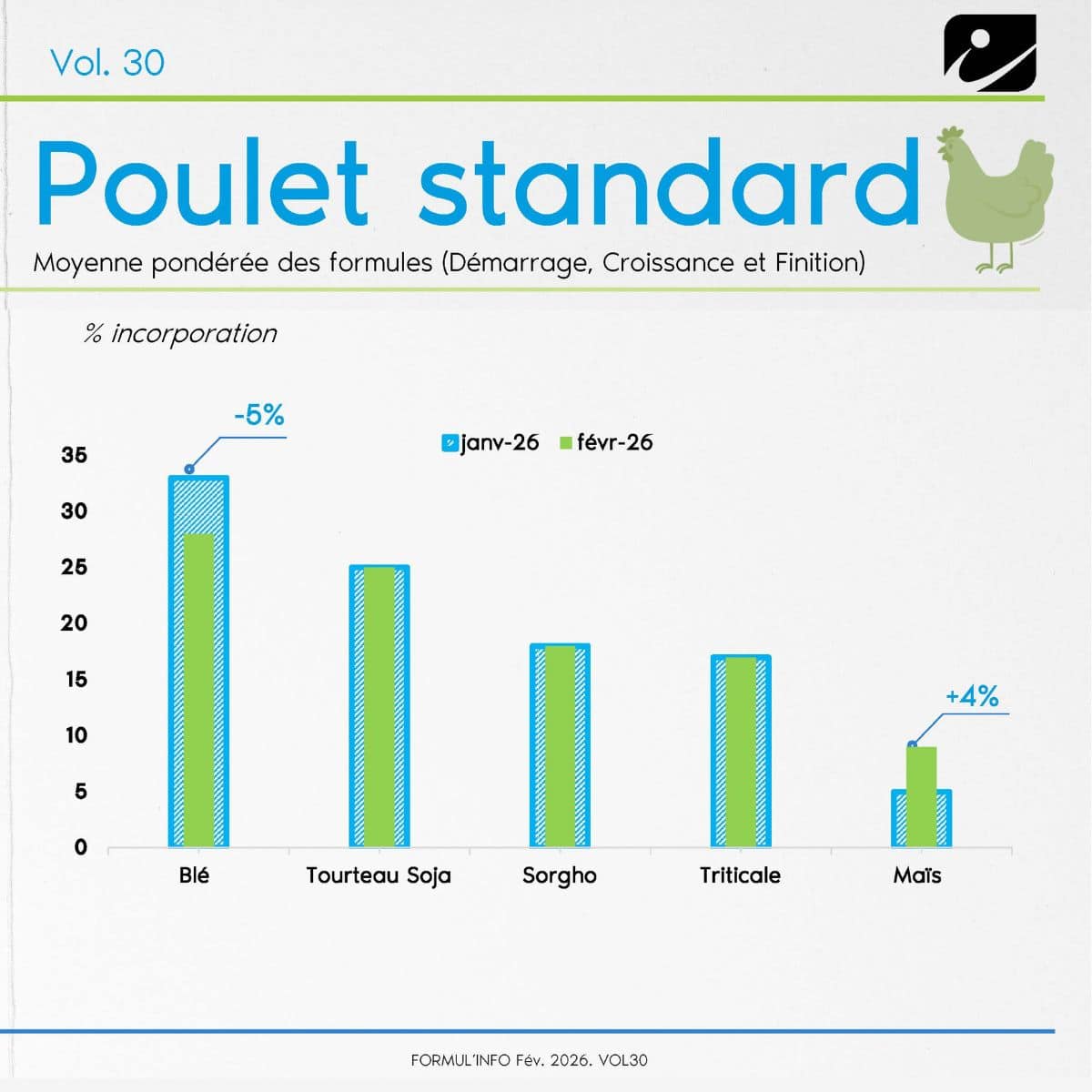

There has been a decline in wheat production in favour of maize, with soybeans, sorghum and triticale remaining stable.

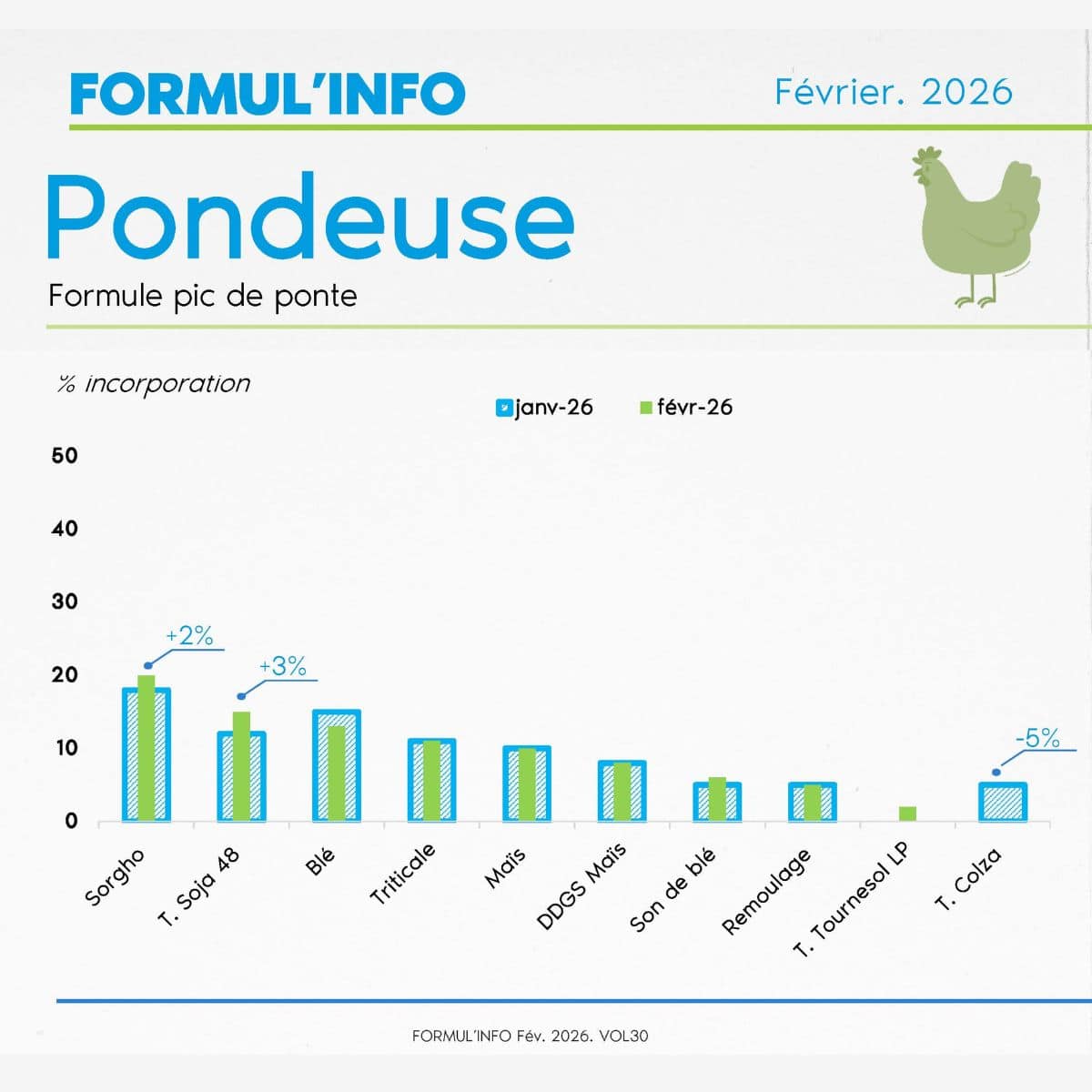

Between January and February, the formula shifts towards the removal of rapeseed, making way for LP sunflower meal and an increase in soya. The wheat content decreases in favour of an increase in sorghum. The rest of the formula remains stable.

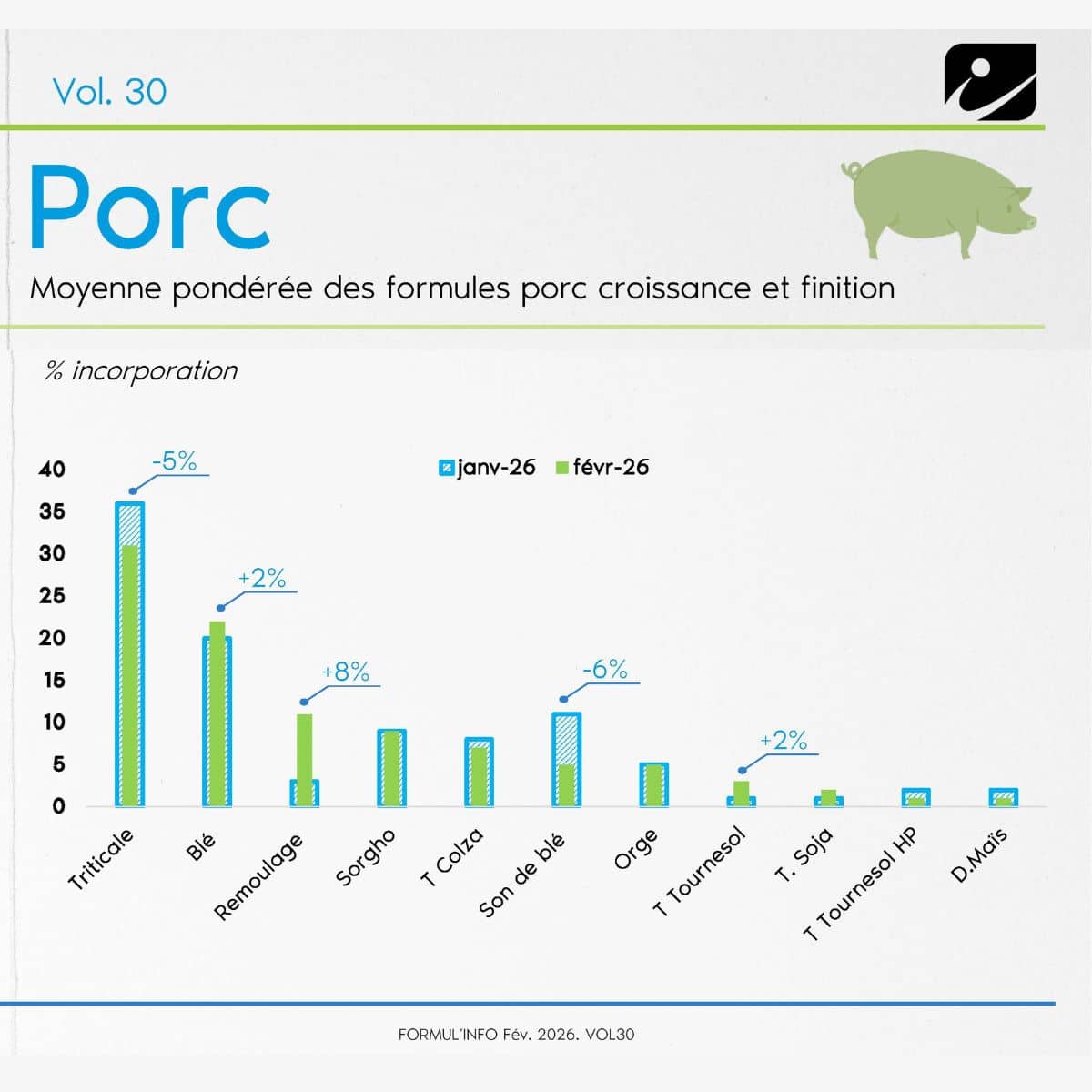

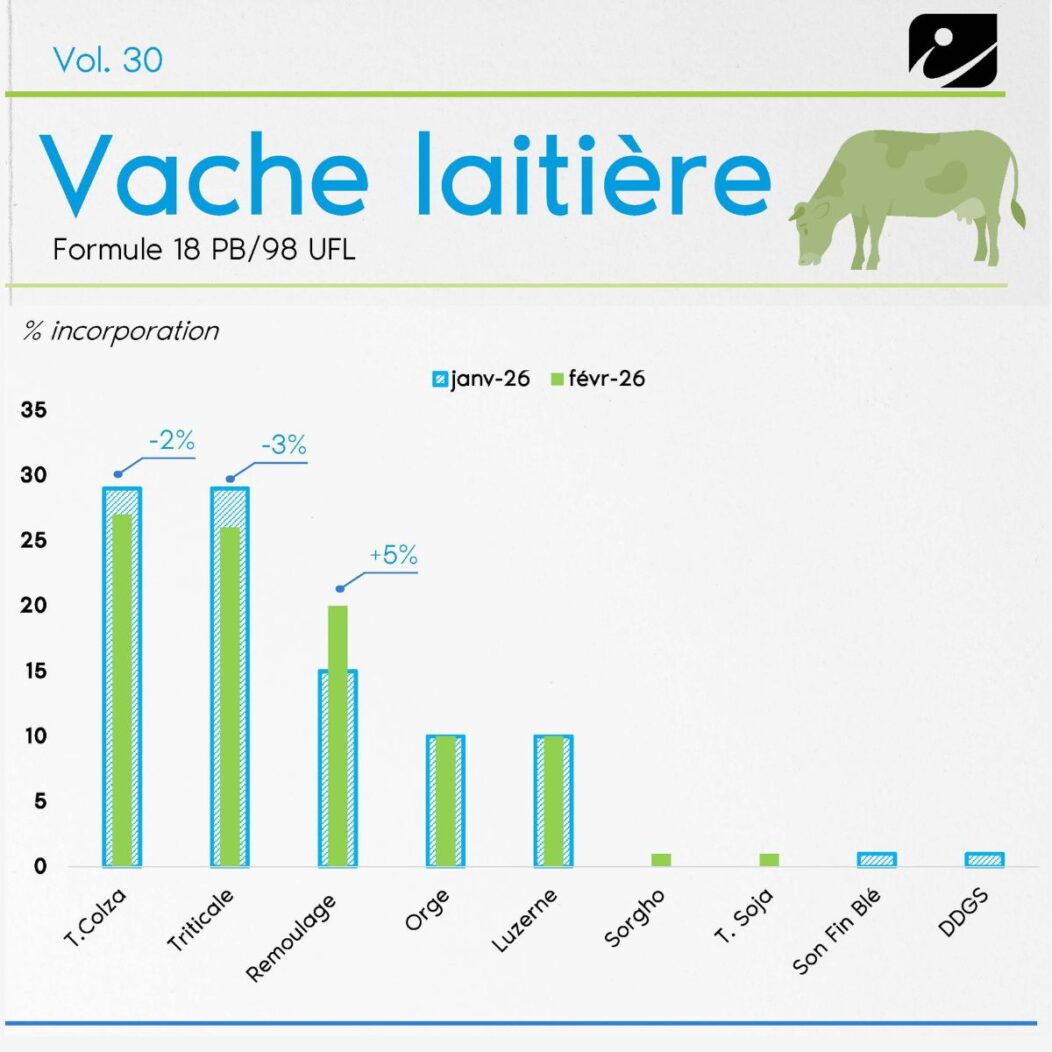

Between January and February, there was a decrease in triticale, offset by an increase in wheat. The increase in re-milling offset the decrease in wheat bran. The protein profile remained stable overall (rapeseed, soya, sunflower at low levels).

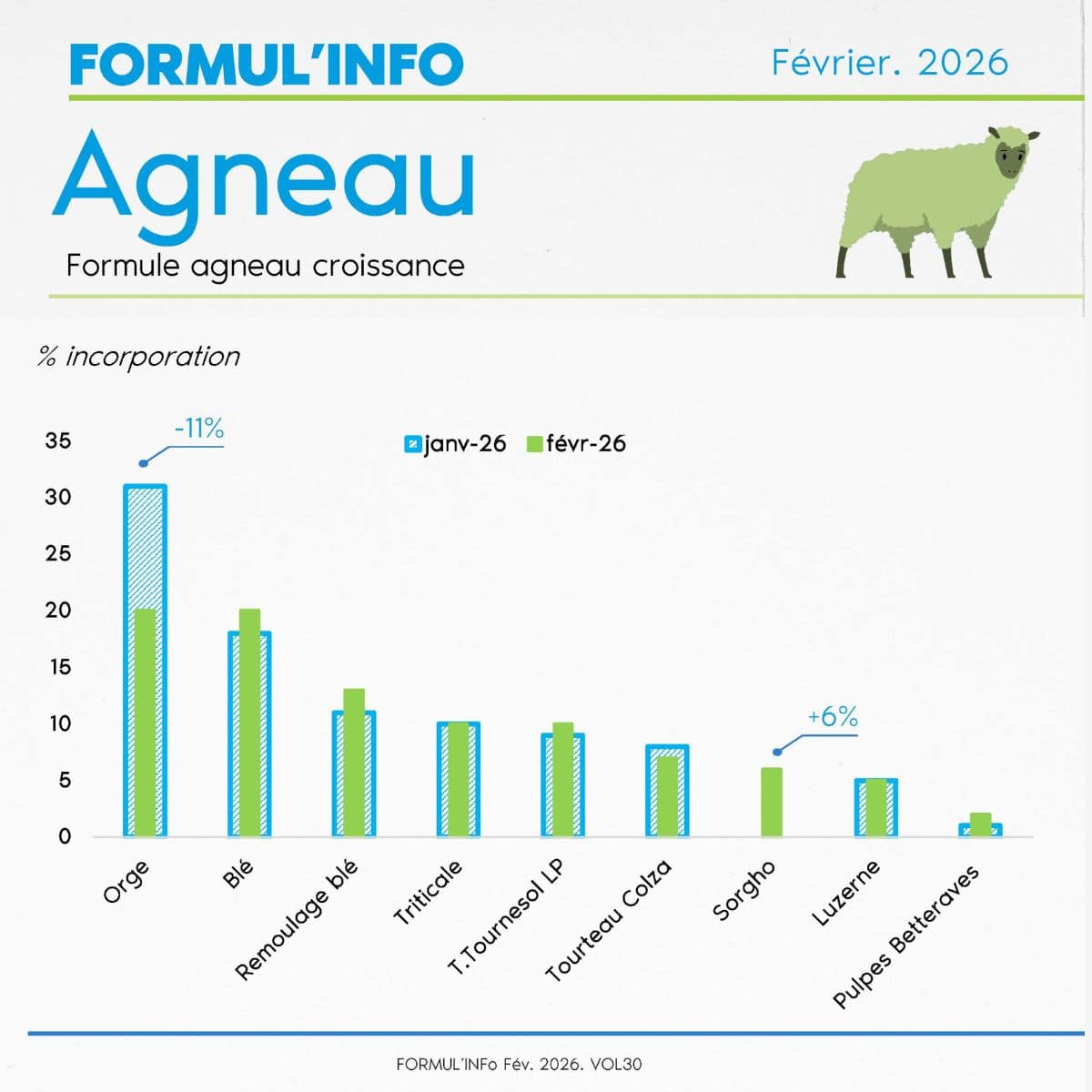

This month, there has been a marked reduction in barley, offset by an increase in wheat and the introduction of sorghum. The decrease in fibre content from barley is offset by an increase in re-milling and beet pulp. The protein profile remains stable overall (LP sunflower and rapeseed meal).

In February, the formula will change to include a slight reduction in triticale, offset by the introduction of sorghum. The reduction in rapeseed will be balanced by the introduction of soya.

Bran and corn distiller’s grains will be completely removed from the formula this month, mainly in favour of re-grinding.

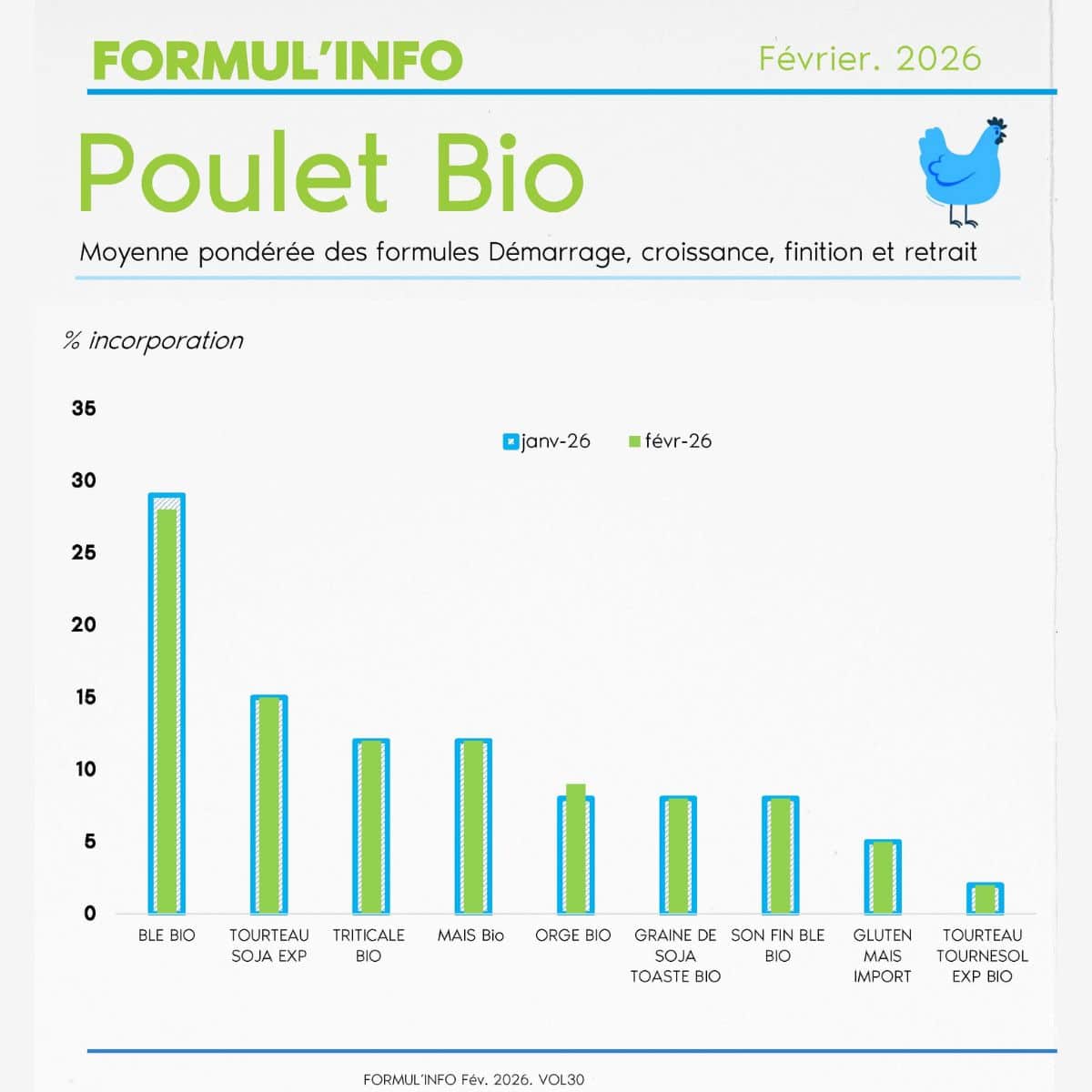

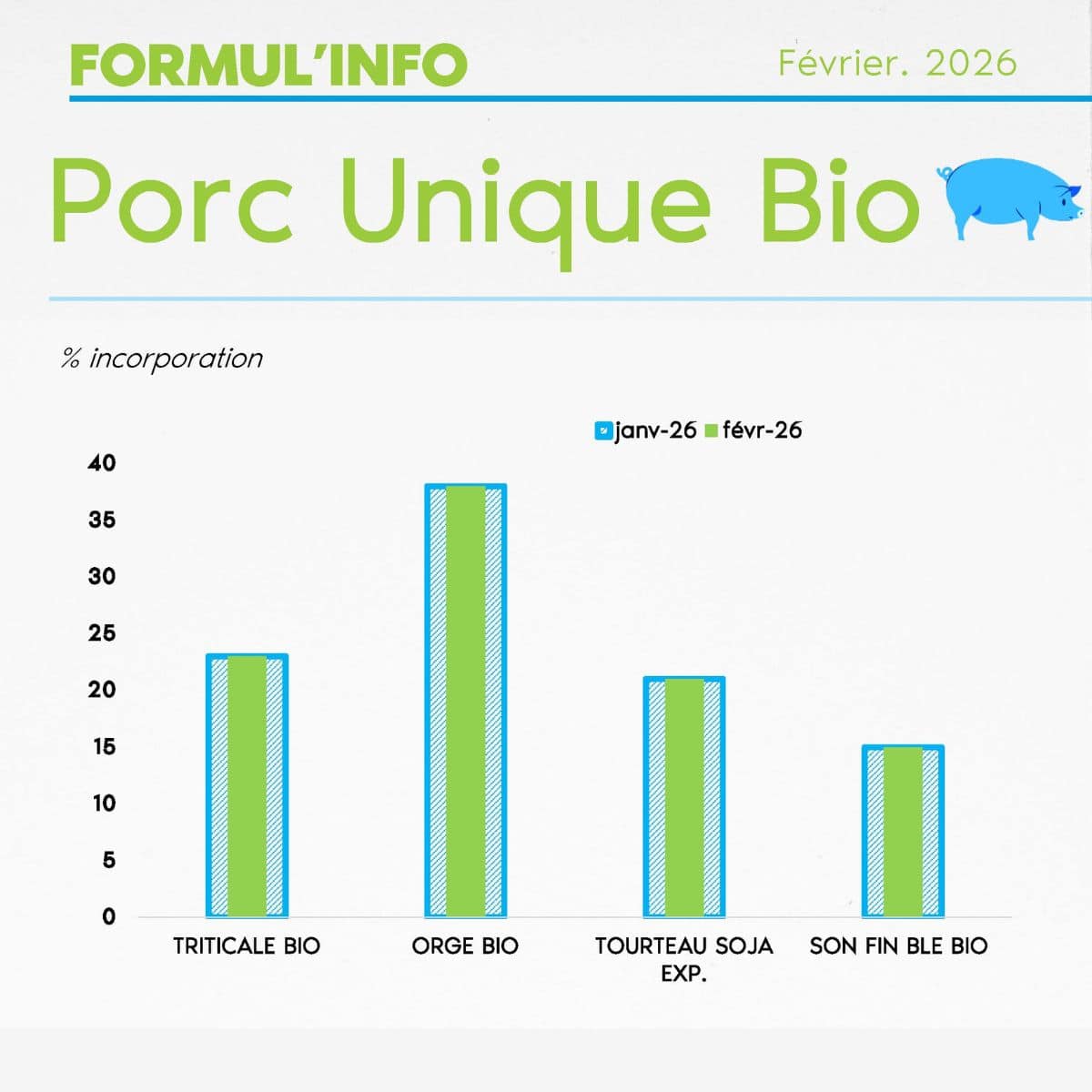

The formula remains stable between January and February.

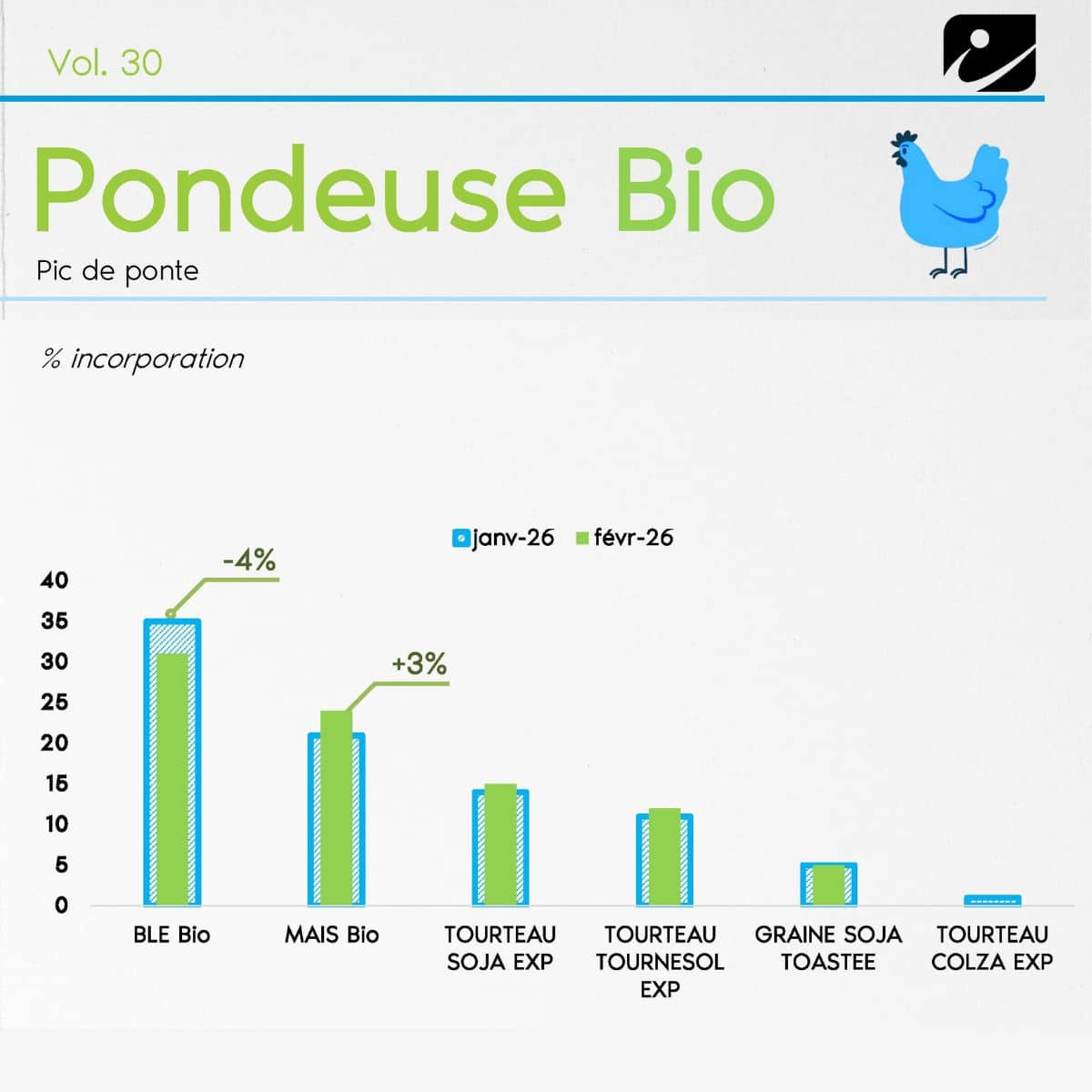

There has been a reduction in wheat, offset by an increase in maize. Soybean and sunflower meal compensate for the decline in rapeseed.

The formula profile is stable compared to the previous month.